Introduction

Hydroxypropyl Methylcellulose (HPMC) is a high-performance, non-ionic cellulose ether widely used in modern building materials. It plays a vital role in improving water retention, workability, and bonding performance in dry mix mortar formulations—particularly in ceramic tile adhesives.

As construction methods evolve toward thinner, larger, and more environmentally friendly tiles, HPMC’s role in ensuring bonding strength and application efficiency becomes increasingly essential.

Key Performance Benefits of HPMC in Tile Adhesive

1. Excellent Water Retention

HPMC forms a protective colloid that retains moisture in mortar systems, ensuring:

Prolonged cement hydration

Stronger adhesion to tile substrates

Reduced risk of tile detachment

Especially effective for:

High water-absorption tiles (porcelain, stone)

High-temperature environments

Thick-bed applications

2. Improved Workability

Thanks to its thickening and rheology modification capabilities, HPMC enhances:

Sag resistance (ideal for vertical tiling)

Smooth trowelability

Extended open time (up to 30–40 minutes)

Tile Adhesive Classification and Recommended HPMC Grades

| Tile Adhesive Type | Required Bond Strength | Suitable Tiles | Recommended HPMC Viscosity | Dosage (%) |

|---|---|---|---|---|

| C1 (General) | ≥ 0.5 MPa | Small ceramic tiles | High | 0.2–0.3% |

| C2 (Enhanced) | ≥ 1.0 MPa | Porcelain, large tiles | Medium | 0.3–0.5% |

| Flexible / White | Varies | Special requirements | Modified grades | Case-by-case |

| Classification | Performance | Indicators |

| C1-General cementitous adhesive | tensile bond strength/MPa | ≥0.5 |

| Tensile bonding strength after immersion in water/MPa | ≥0.5 | |

| Tensile bonding strength after thermal aging/MPa | ≥0.5 | |

| Tensile bonding strength after freeze-thaw cycles/MPa | ≥0.5 | |

| Open time ≥ 20 min, tensile bonding strength/MPa | ≥0.5 | |

| C2-Enhanced cementitous adhesive | tensile bond strength/MPa | ≥1.0 |

| Tensile bonding strength after immersion in water/MPa | ≥1.0 | |

| Tensile bonding strength after thermal aging/MPa | ≥1.0 | |

| Tensile bonding strength after freeze-thaw cycles/MPa | ≥1.0 | |

| Open time ≥ 20 min, tensile bonding strength/MPa | ≥0.5 |

Key Factors Influencing HPMC Performance

Viscosity Grade

Low: 15,000–40,000 mPa·s (thin-bed applications)

Medium: 40,000–80,000 mPa·s (standard)

High: 80,000–150,000 mPa·s (thick-bed applications)

Particle Size

Finer particles dissolve quickly

Coarser particles extend open time

Additive Compatibility

Celotech’s Recommended Products for Tile Adhesives

Recommended HPMC Grades for Different Tile Adhesive Classes:

| Product Name | Viscosity | Recommend Application | C1 | C2 | C2S1 |

|---|---|---|---|---|---|

| Celopro® MT2030 | Low | C1TE / C2TE / C2TES1 | ●●● | ●● | ●●● |

| Celopro® MT4016 | Medium | C1TE / C2TE / C2TES1 | ●●● | ●●● | ●● |

| Celopro® MT6510 | High | C1TE / C2TE / C2TES1 | ●●● | ●● | ●● |

| Celopro® MT6108 | Medium | C1TE / C2TE | ●●● | ● | ●● |

| Celopro® ME50M | Medium (Modified) | C1TE / C2TE | ●●● | ●●● | ●● |

| Celopro® ME70M | High (Modified) | C1TE / C2TE | ●●● | ●● | ● |

(●●●= Highly Recommended ; ●●= Recommended ; ●= Optional/Case-by-case)

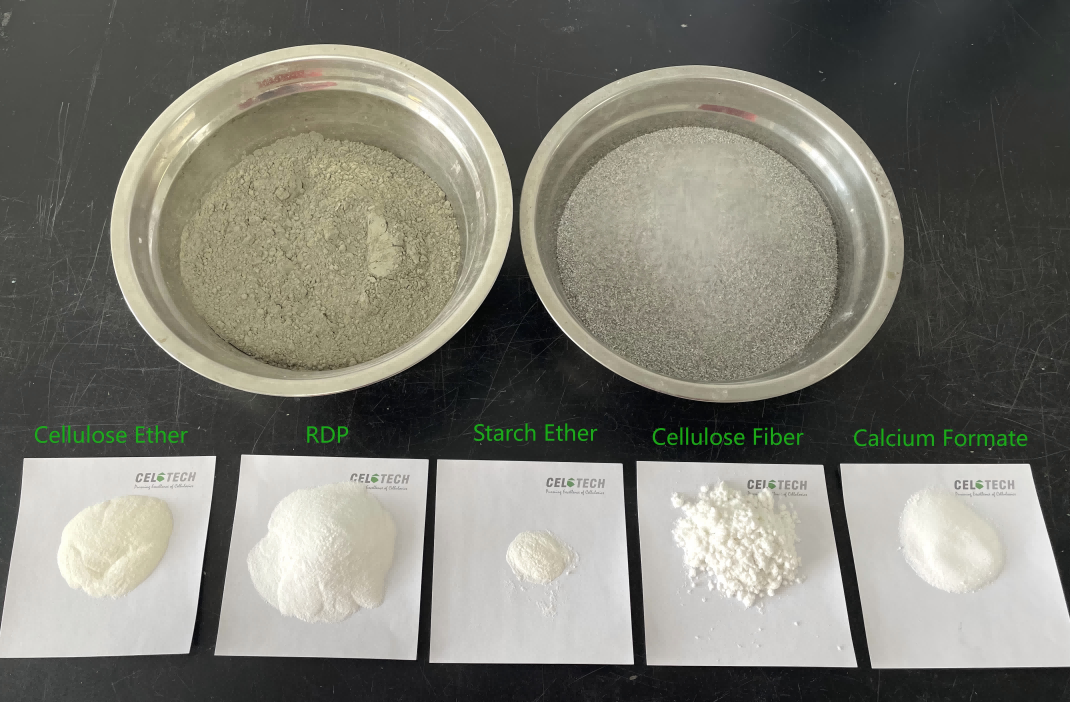

Additive Compatibility Chart:

| Additive Type | Product Name | Feature | Compatible Grades |

|---|---|---|---|

| RDP | Vinabond® N511 | Rigid (Vac/E) | C1TE, C2TE |

| Vinabond® N515 | Neutral (Vac/E) | C1TE, C2TE, C2TES1 | |

| Vinabond® N516 | Flexible (Vac/E) | C2TES1 | |

| Starch Ether | Stargel® ST600 | HPS | C1TE, C2TE, C2TES1 |

| Cellulose Fiber | Celofiber® CF300W | 300 µm, white | C1TE, C2TE, C2TES1 |

| Early Strength Agent | Quickset® S98 | Calcium Formate | C1TE, C2TE, C2TES1 |

Market Trend and Conclusion

With global demand for ceramic tile adhesives rising, high-quality additives like HPMC are more crucial than ever. The Chinese government’s “14th Five-Year Plan” promotes pre-mixed mortar, accelerating HPMC adoption in eco-friendly formulations.

HPMC enhances bonding strength through water retention, workability improvement, and superior adhesion—ensuring reliable, long-lasting tile installations.

Celotech provides a wide range of modified and pure HPMC grades tailored to specific application needs in wall putty, tile adhesives, tile grouts, and more.

Frequently Asked Questions (FAQ)

Q1: What is the recommended dosage of HPMC in tile adhesives?

A: Typically 0.2%–0.5%, depending on tile type and adhesive classification (C1/C2).

Q2: How does HPMC improve tile adhesive open time?

A: HPMC delays water evaporation and maintains workability for 30–40 minutes after application.

Q3: What’s the difference between low and high-viscosity HPMC?

A: Low-viscosity is ideal for thin-bed adhesives, while high-viscosity is used in thick-bed or high-sag-resistance formulations.

Q4: Is HPMC compatible with RDP and starch ether?

A: Yes. Compatibility with additives like Vinabond® RDP and Stargel® enhances overall performance.

Q5: Does Celotech offer custom formulations?

A: Absolutely. We tailor HPMC and other additives based on your specific tile adhesive performance requirements.