With the continuous development of the construction industry, the performance requirements of materials for ground construction are getting higher and higher. Cement-based self-leveling mortar, as an efficient and convenient ground-leveling material, has gradually been widely used. The application of the ternary gel system in cement-based self-leveling mortar has provided a strong impetus for its performance improvement and market promotion.

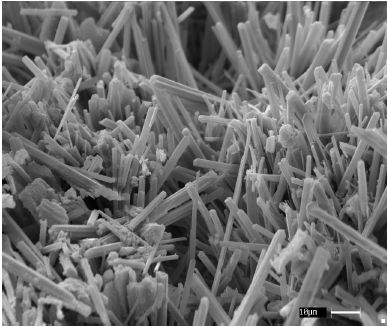

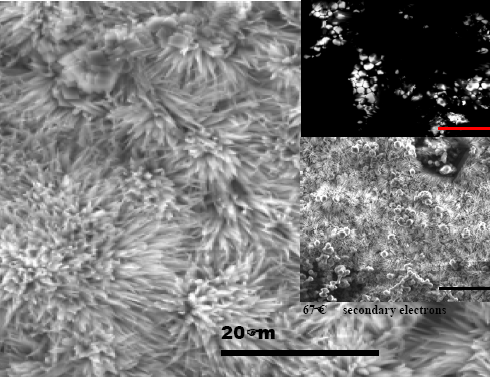

1. The Key Role of Ettringite (AFt) Formation

The formation of ettringite (C3A·3CaSO4·32H2O) is a crucial factor in the ternary binder system. Ettringite has rapid formation ability, high bound water capacity, and shrinkage compensation properties, which help self-leveling mortar achieve rapid hardening, low shrinkage, and improved durability.

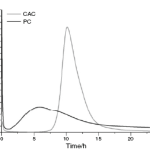

2. Composition of the Ternary Binder System

The most common ternary binder system consists of:

- Ordinary Portland Cement (OPC): C3S, C2S, C3A, C4AF, gypsum

- Sulphoaluminate Cement (SAC) :C4A3S, C2S, C4AF, anhydrite, lime

- Calcium Aluminate Cement (CAC): CA, CA2, C2AS

- Gypsum

AFt Forming:

- C3A + 3CaSO4 + 32H2O → C3A · 3CaSO4 · 32H2O (ettringite, AFt)

- CA+3CaSO4+2Ca(OH)2+30H2O→AFt

- CA+3CaSO4+38H2O→AFt+2Al(OH)3

- C4A3S + 8CaSO4 + 6Ca(OH)2 + 90H2O → 3AFt

- C4A3S+2CaSO4+38H2O→AFt+2Al(OH)3

- AFm+2CaSO4+20H2O→AFt

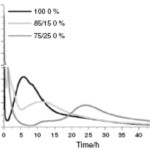

3. Challenges of AFt Formation

While AFt offers many benefits, it can also pose challenges:

- In the early hydration stage, excessive ettringite may coat unhydrated cement, affecting strength development.

- In the hardening stage, excessive ettringite may cause expansion and cracking.

- Variations in cement compositions across different manufacturers and regions necessitate extensive testing to determine the optimal ratio of OPC, SAC, CAC, and gypsum.

4. Raw Materials and Their Functions in the Ternary Binder System

To achieve optimal performance, self-leveling mortar formulations include the following materials:

| Raw Material | Grade | Dosage (kg/t) | Function | |

|---|---|---|---|---|

| Cement | P.O 42.5 | 250-350 | Provide strength | |

| Sulphoaluminate cement | 50-150 | Provide early strength | ||

| Calcium aluminate cement | 50-100 | Improve expansion | ||

| Gypsum | Anhydrite | 20-30 | 30-50 | Improve expansion |

| Sand | 80 – 200 mesh | 400-450 | Aggregate | |

| Calcium carbonate | 200 – 400 mesh | 150-200 | Filler | |

| Cellulose ether | Celopro® MT1004 | 0.6-1.2 | Improve suspensibility | |

| RDP | Vinabond® N511 Vinabond® N515 | 10.0-20.0 | Anti-crack, improve adhesion strength,Improve wear resistance | |

| Superplasticizer | Ultraplast® PC16 | 1.0-1.5 | Improve fluidity | |

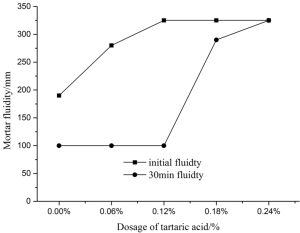

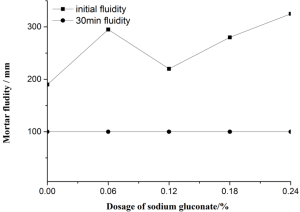

| Retarder | Tartaric acid / sodium gluconate | 0.5-1.0 | Extend setting time | |

| Defoamer | Foamsolver® DF03 | 1.0-2.0 | Improve strength, good surface | |

5. The Role of Additives in Ternary Binder Systems

Due to the complexity of the raw materials, additives must be highly adaptable. Some essential additives include:

- High-efficiency water reducers: Ensure fluidity and prevent excessive fluidity loss.

- Ultraplast® PC16: Provides a high water reduction rate, helping customers reduce costs.

- Ultraplast® PC10: Reduces fluidity loss and maintains workability.

- Retarders: Extend setting time and prevent premature hardening.

- Sodium gluconate and tartaric acid are widely used.

- Redispersible Powder (RDP): Enhances adhesion, flexibility, and crack resistance.

- Vinabond® N511 and Vinabond® N515 improve adhesion and wear resistance.

- Defoamers: Improve the surface quality and strength of the mortar.

- Foamsolver® DF03 ensures a smooth finish and prevents defects.

Conclusion

The ternary binder system plays a key role in cement-based self-leveling mortars, allowing for fast hardening, good water retention, and low shrinkage. However, achieving optimal performance requires precise formulation to prevent excessive expansion and cracking.

A well-balanced combination of cement, gypsum, and high-quality additives—such as Celopro® MT1004 (a premium HPMC for construction), Vinabond® N511 (a reliable RDP powder), and Ultraplast® PC16—can significantly enhance workability, adhesion, and durability. As an experienced HPMC manufacturer and supplier, Celotech provides top-grade cellulose ethers that ensure excellent water retention and smooth application in self-leveling mortars.

With the right formulation, self-leveling mortars achieve superior performance, making them ideal for flooring applications. Choosing a trusted HPMC supplier and RDP powder supplier ensures consistent quality, helping construction professionals meet the demands of modern building projects.

For more information, visit www.celotech.com.