You will notice mortar mix with HPMC dries slower than regular mortar. The drying time can go from 3 hours to more than 10 hours. HPMC makes the mortar dry slowly. This helps you work with the mortar longer. It also helps the mortar stick better. Pick Hydroxypropyl Methylcellulose from good brands like Celotech. This gives you steady results.

- Adding hpmc makes the mortar take longer to set. This makes it easier to use.

- Slower drying helps the mortar hold water better and stick well.

Key Takeaways

- Mortar with HPMC dries slower than normal mortar. It takes 3 to 10 hours to start setting. This gives you more time to work and make changes.

- Mortar with HPMC needs about 28 days to fully cure. You need to wait for a strong and lasting finish.

- Using the right amount of HPMC helps a lot. Use between 0.1% and 0.5%. This keeps water in the mix and makes it easier to use. You will get better results.

- Temperature and humidity change how fast mortar dries. Warm weather makes it dry faster. Cool and wet weather makes it dry slower.

- Always follow good steps when working with mortar. Mix HPMC with water first. Keep the mortar wet while it cures. This helps you avoid mistakes.

Drying Time

Initial Set

When you mix mortar with hpmc, you notice the initial set takes longer than regular mortar. The initial set is when the mortar starts to harden and can hold its shape. You usually see this happen between 3 and 10 hours after mixing. The exact time depends on how much water you use, the temperature, and the thickness of the layer.

Hpmc helps the mortar keep water inside. This slows down the drying process. You get more time to work with the mortar and make adjustments. If you work in a warm room, the mortar sets faster. If you work in a cool or humid place, the setting time increases.

Tip: Always check the mortar before adding tiles or bricks. Press gently with your finger. If the surface feels firm and does not move, the initial set is complete.

Full Cure

The full cure is when the mortar reaches its maximum strength. You need to wait for this stage before putting heavy loads or finishing work. Mortar with hpmc usually takes about 28 days to fully cure under normal conditions. You should not rush this process. If you do, the mortar can become weak or brittle.

Here is what you should know about full curing time:

- Mortar needs about 28 days to reach full strength.

- Temperature and humidity can change the curing time.

- Waiting for the full cure gives you a strong and durable finish.

You can use a table to track the curing stages:

| Stage | Time Needed | What to Check |

|---|---|---|

| Initial Set | 3-10 hours | Surface feels firm |

| Full Cure | ~28 days | Ready for heavy loads |

Note: Choose high-quality brands of hydroxypropyl methylcellulose such as Celotech, which will bring you stable results.

HPMC in Mortar

Hydroxypropyl Methylcellulose (HPMC) from Celotech is widely used in mortar mixes today. It improves construction performance by enhancing workability, adhesion, and consistency. With these benefits, HPMC has become a preferred choice for many builders and contractors.

Water Retention

You want mortar to stay wet long enough to cure right. HPMC forms a thin layer around cement pieces. This layer slows water loss and keeps the mix wet. When you use HPMC, mortar does not dry too fast. Tests show HPMC makes a network that holds water. This stops water from leaving the mix quickly. Your mortar will be stronger and have fewer cracks.

- HPMC can keep up to 94% more water if you use more.

- More water means better curing and stronger mortar.

Workability

You want mortar that is easy to spread and shape. HPMC makes the mix smoother and less sticky. It lowers friction between the pieces in the mix. You can spread mortar with less work. The mortar flows better and fills spaces easily. This helps when you lay bricks, plaster walls, or set tiles.

Tip: Use the jumping table or slump cone to check how thick your mortar is. Good thickness means mortar keeps its shape and sticks well.

Dosage

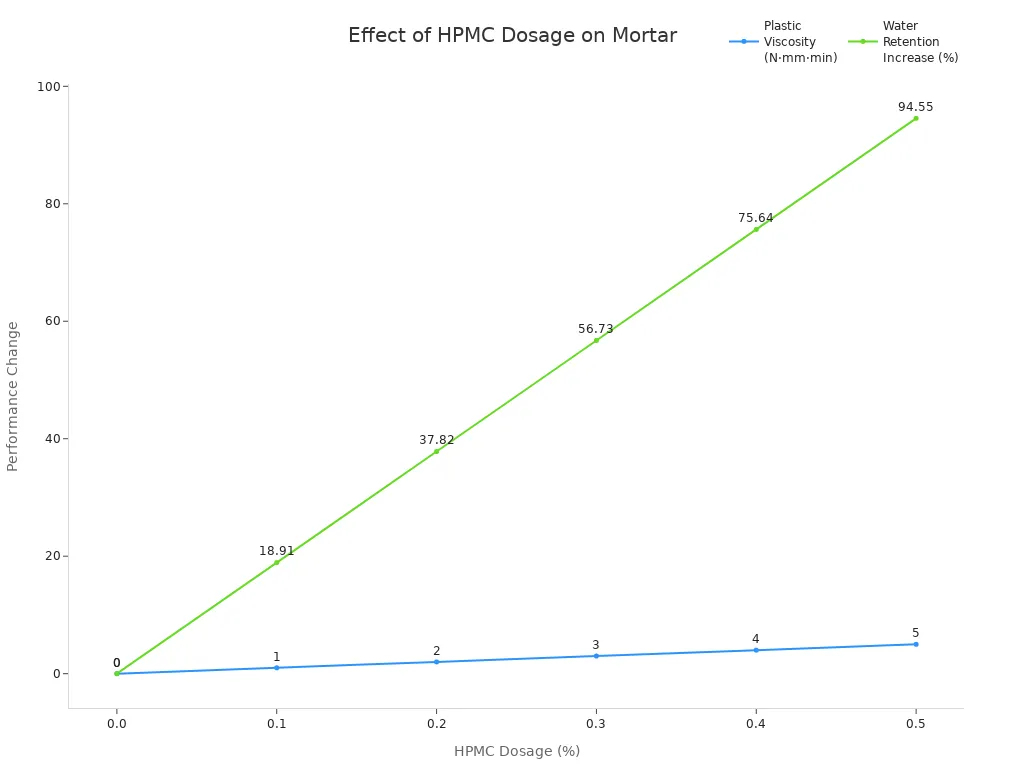

You need to watch how much HPMC you put in the mix. The best amount is between 0.1% and 0.5% of the dry mix. Using the right amount gives you good water holding and easy spreading. If you add more, you get thicker mortar and more water holding. The table below shows this.

| HPMC Dosage (%) | Plastic Viscosity (N·mm·min) | Water Retention Increase (%) |

|---|---|---|

| 0.0 | Baseline | Baseline |

| 0.1 | +1 | +18.91 |

| 0.2 | +2 | +37.82 |

| 0.3 | +3 | +56.73 |

| 0.4 | +4 | +75.64 |

| 0.5 | +5 | +94.55 |

You can use HPMC for many jobs like masonry, plastering, tile glue, and fixing mortar. Always follow what the supplier says for best results.

Influencing Factors

Temperature & Humidity

You must watch the weather when using mortar with HPMC. Warm weather makes the mortar dry faster. Cool or wet air slows down drying. High humidity keeps water in the mortar longer. This means you wait more for it to dry. In hot, dry places, HPMC helps hold water. This stops the mortar from drying too fast and getting weak. If you work outside, check the weather first. Cover your work if rain or high humidity might happen. Doing this protects your mortar and makes it stronger.

Tip: Try to work when the weather is not too hot or cold. This helps you control how fast the mortar dries and get better results.

Mix Ratio & Thickness

How you mix cement, sand, and water changes drying time. More water makes the mortar soak up more and get tiny holes. This slows drying and makes the mortar weaker. Always measure your ingredients well.

- More water in the mix means more soaking and tiny holes.

- Mortar gets weaker if you add extra water.

- Tests show more water makes drying take longer.

Layer thickness matters too. Thick layers keep water inside. This makes it hard for water to leave. Thin layers dry faster because air can reach more spots. For best results, use thin layers. This helps the mortar dry quicker and lets you finish sooner.

Additives

You can add other things with HPMC to change how the mortar dries and works. Some mixes help the mortar stick better, bend more, and keep out water. Others make it stronger or easier to spread. The table below shows how different additives work with HPMC:

| Additive Combination | Effects on Mortar Properties |

|---|---|

| HPMC/HEMC + RDP + HPS | Makes mortar stick, bend, and spread better |

| PCE + RDP | Helps mortar flow and get stronger |

| SHP + RDP | Makes mortar keep out water |

| HPMC + RDP + PCE | Helps mortar stick and last longer |

Adding 0.20% HPMC slows drying the most. HPMC keeps water in the mix. This helps curing but makes drying slower. If you want faster drying, use less HPMC or add things that help water leave. Always follow what the supplier says for the best results.

Practical Tips

Best Practices

You can get the best results from mortar with HPMC by following a few key steps. Always measure the HPMC carefully. Use the amount recommended for your type of mortar and water-cement ratio. This helps you get the right mix every time.

Start by mixing HPMC with water before adding dry ingredients. This step prevents clumping and ensures the HPMC spreads evenly through the mix. Gradually add water as you mix. You want a smooth, workable texture without making the mortar too wet.

Keep the mortar moist for at least 24 hours after you apply it. Cover it with a damp cloth or plastic sheet. This helps the cement hydrate fully and gives your mortar more strength.

Try to work when the temperature is not too hot or cold. Good weather helps the mortar dry at the right speed. Use a trowel or sprayer to apply the mortar evenly. This prevents dry spots and helps the mortar stick better.

Here are some best practices to follow:

- Dose HPMC within the recommended range.

- Mix HPMC with water first for even distribution.

- Follow the manufacturer’s curing instructions.

- Gradually add water to reach the right consistency.

- Apply mortar evenly and keep it moist during curing.

Mistakes to Avoid

You can avoid many problems by watching out for common mistakes. Using the wrong type of mortar or the wrong water-to-mix ratio can weaken your project. If you do not mix the mortar well, you may see cracks or weak spots.

Do not rush the curing process. If you let the mortar dry too fast, it will not reach full strength. Always allow enough time for curing.

Here are some mistakes to avoid:

- Using the wrong mortar type.

- Adding too much or too little water.

- Mixing poorly, which can cause lumps.

- Skipping proper curing steps.

| Consequence | Description |

|---|---|

| Increased Viscosity | Too much HPMC makes the mix hard to spread. |

| Uneven Curing Times | Wrong dosage can slow or speed up curing, hurting the final result. |

| Poor Adhesion | Not enough HPMC leads to weak bonds and possible tile slippage. |

| Difficulty in Spreading | High viscosity causes the mortar to stick to tools and makes work harder. |

| Clumping and Inconsistencies | Bad mixing creates lumps and weak spots in the mortar. |

Remember, careful mixing and curing help you get strong, long-lasting mortar every time.

You now know that using hpmc in mortar helps you get better results. HPMC keeps water in the mix, which lets the cement hydrate well and makes the mortar stronger. You also get more time to work before it dries. High-quality hpmc improves workability and helps prevent cracks. Always follow best practices and choose trusted brands for reliable drying times and a durable finish.

FAQ

How does HPMC affect mortar drying time?

HPMC slows down the drying process. You get more time to work with the mortar. This helps you make adjustments and get a better finish.

Can I speed up mortar drying if I use HPMC?

You can work in a warm, dry place to help the mortar dry faster. Use thinner layers. Always follow the supplier’s advice for best results.

What is the best HPMC dosage for mortar?

You should use between 0.1% and 0.5% of the dry mix weight. This range gives you good water retention and workability. Check the product label for exact amounts.

Why does my mortar feel sticky when I use HPMC?

Too much HPMC can make the mortar sticky and hard to spread. Measure the HPMC carefully. Mix it well with water before adding other ingredients.

Can I use mortar with HPMC for outdoor projects?

Yes, you can use mortar with HPMC outside. It helps the mortar stay strong and resist cracks. Protect your work from rain and extreme weather for the best results.